Mazak AJV Series Spindle Repair & Rebuild

Mazak AJV-25-404

At High Speed Technologies we offer expert Mazak Spindle Repair and Rebuild. Dating back to the early 1900’s, Mazak has been around for a while. Incorporated since the early 1980’s, we at High Speed Technologies have seen our fair share of Mazak spindles. Call today with your Mazak spindle repair questions 1-603-483-0333

When this Mazak AJV hit our dock it was seized hard and the shaft taper was damaged. Upon removal of the bearing stack we found the #1 bearing had failed. Also, the rear bearing journal was undersized causing the rear roller bearing to fit loose and spin freely. This shaft surface required Grind-Plate-Grind for proper roller bearing fit. Being a straight bore roller bearing, proper fit to the shaft is critical. If it fits too loose or too tight the bearing will fail in short time.

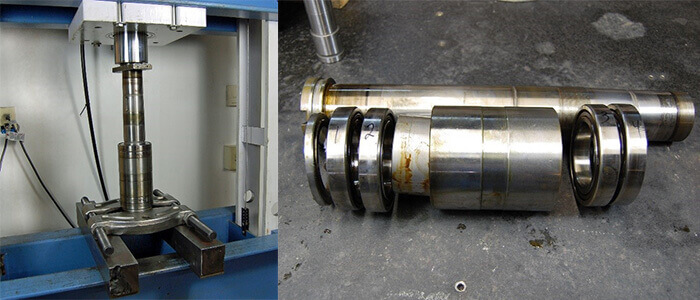

Removing bearing stack on a Mazak AJV

After the bearing stack was carefully pressed off of the shaft, we found the grease lubrication within each bearing to be washed with cutting fluid and metal particulate. The resulting lack of lubrication and foreign particulate destroyed the front bearings. The rear bearing pair was very worn but operable. We also observed damage to the rear end of the shaft indicating that the rear roller bearings inner race was spinning freely. This likely resulted in excessive spindle vibration and poor finish quality. As usual, all bearings were replaced in kind with top name brand ABEC 7 bearings. Also, several of the Belleville washers on the Drawbar were broken and had been causing tool holding issues. We replaced all Belleville washers with new but the gripper assembly was in good condition and was re-used.

#1 bearing contaminated and failed. #5 Rear roller bearing fit loose on the shaft journal. Broken Belleville washers. Likely resulted in tool holding issues.

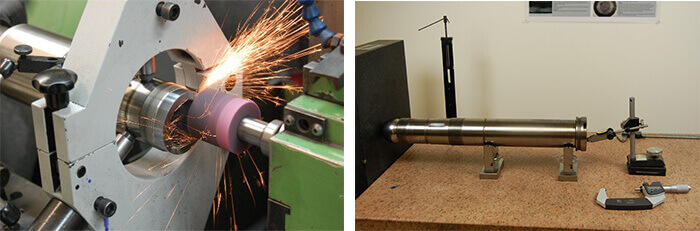

Once the bearings were removed from the shaft we were able to examine both the bearings and the shaft more closely. The #1 bearings ball cage was destroyed and the rear roller bearing was badly worn. The shaft taper ID had excessive runout. With our in house Kellenberger Universal Grinder we were able to eliminate 8 microns of runout with a Kiss Grind and restore the rear roller bearing surface to within specification with our Grind-Plate-Grind process.

Kiss Grinding a Mazak AJV spindle and Inspecting the taper of Mazak AJV

Once all repairs on this Mazak AJV were completed it was up and running smoothly! If you have a Mazak spindle that needs repair call High Speed Technologies today. 1-603-483-0333.