Boneham Spindle Repair & Rebuild

Boneham HFGS816T

At High Speed Technologies our Boneham spindle repair and rebuild comes with a one year warranty. HST has more than 30 years of experience repairing spindles. Here at our clean room facility we go the extra mile to return your Boneham spindle to new condition. When we’re done with it, it not only runs like new but it looks like new! Call today with your Boneham spindle repair questions 1-603-483-0333.

Job: I7912

This spindle was received in very poor condition! Covered in a thick coat of silica, it took almost as much time to disassemble and clean the spindle as it did to assemble and test it. Nearly every bolt was stripped out and had to be drilled out. Upon receipt the shaft taper was also badly damaged. The damage was the result of excessive force while attempting to remove a stuck quill with the wrong tool. The lubrication within each bearing was extremely contaminated and virtually non-existent. The combination of particulate contamination and degradation of lubrication destroyed all bearings. After restoring the shaft taper with our G-P-G process we replaced all bearings and seals. We also replaced the power connector and connector housing. After trim balancing the rotating components the spindle ran excellent. We ran this spindle with the mating connector to verify that the connector was wired properly and the shaft was rotating in the proper direction. We even supplied the customer with a new wrench which will allow them to remove their quill without damaging the shaft in the future.

Left & middle photo: All Bearings were found to be Severely Contaminated.

Right photo: Note Severe Deterioration of Power Connector

Job: I8097

Upon receipt there were no customer comments but we could tell with a glance that this Boneham spindle had seen better days. We measured just over 40 microns of runout at the taper ID and the wrench flats were chewed up and rounded over. Once the spindle was completely dismantled a visual inspection revealed each bearing to be completely void of lubrication and filled with foreign particulate. This combination of lubrication degradation and contamination over time resulted in total bearing failure; the front pair’s phenolic cages were both destroyed. Also, the front housing bore (ID) was +30 micron over-sized resulting in a loose bearing fit and excessive vibration. After returning the shaft and housing bore to within bearing specification we replaced all bearings with ABEC 7 name brand bearings, replaced all seals and the electrical power connector assembly. The stator was also washed, baked and surge tested as a precaution. When we were completed with the repairs the spindle ran as good as it did the day it was first installed into the machine.

Job: I8315

This Boneham spindle came in from one of our customers who is a leader in engineered ceramics and other materials. Their complaint was a little vague, “spindle not working properly.” Without taking the spindle apart we found what we believed to be the chief problem. The stator had shorted to ground. But what had caused this? As you see in the pictures below, a severe amount of cutting fluid had migrated into the spindle causing the stator to short out. Rather than assume a destroyed stator and send it out for and expensive rewind, in this situation we sent it to an independent third party motor expert for a wash, bake and surge test. In this case the stator turned out to be just fine, which saved the customer hundreds of dollars. With the stator now clean and dry it was re-installed into the main housing and re-tested. All bearings and seals were replaced with new. After passing all performance tests, the spindle was painted with a two part Hi-Solid epoxy paint and the spindle was neatly and tightly packaged for safe transport back to the customer.

Job: I0490

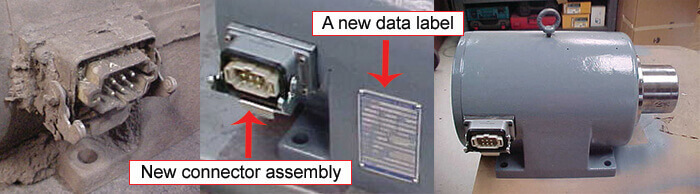

The main reason this spindle was sent in was because of the damage to the shaft taper ID. Grinding particulate had worked its way between the shaft taper and the tool which resulted in subsequent damage. The taper had 60 microns of runout and the face 100! After G-P-G we measured just under a micron on both the shaft taper and face! After replacing all of the bearings, electrical connector and seals with new the spindle ran excellent. This spindle was repaired over three years ago and it’s still alive and grinding!

Left photo: Connector will be replaced with new.

Middle photo: Shaft taper ID needed GPG.

Right photo: Contaminated bearing

These are just a few of the Boneham spindles we’ve had the opportunity to service recently. Having rebuilt over 200 of them over the past few years, we could write a book on the subject. It’s safe to say that we are very confident in our Boneham spindle repairs. Replacing power connector assemblies, new legible data labels, providing two-part industrial epoxy paint that doesn’t wash off within seconds of install, supplying proper tooling for more delicate quill removal; this is all evidence that our team truly takes pride in going the extra mile for your Boneham spindle repair! If you have questions regarding your spindle, call today 1-603-483-0333!