Bridgeport Spindle Repair and Rebuild

Your Bridgeport spindle is in expert hands with the factory-trained, Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of Bridgeport spindles to original factory performance. Need it fast? We can repair your spindle within three days of customer approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are some common Bridgeport spindle performance issues that we resolve:

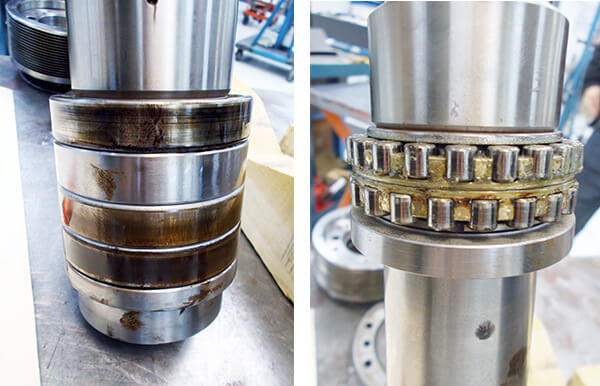

- Noisy or contaminated bearings

- Increased vibration

- Chatter marks

- Blunt force trauma

- Burned stator

- Fatigued springs

- Poor part finish

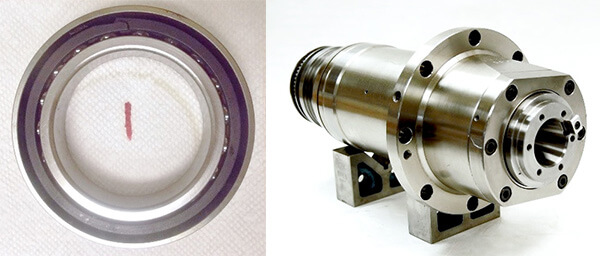

- Failed seal

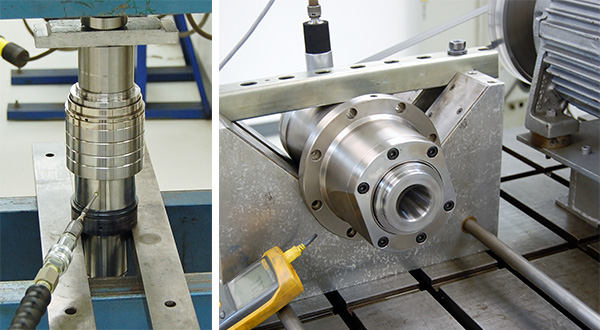

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will include replacing or restoring all worn drawbar springs, seals and critical surfaces. Then we perform high-speed balancing to eliminate vibration, extend life and improve part quality. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986.

Bridgeport VMC3020

The Bridgeport spindle offer robust design. They use standard size bearings and a basic repair can be accomplished in a few days. They have grease bearings that typically require 5–8 hours for proper run-in.

Below are other examples of HST’s OEM-quality repairs on Bridgeport spindles.

For expert Bridgeport spindle repair, call us at 1-603-483-0333 for a quote. We are fast, experienced, and our work is guaranteed.

Featured Repairs

When I was a young maintenance mechanic in a mold making shop back in Brooklyn, NY an Old Portuguese mold maker showed me how to set the dials on the Bridgeport Master Milling machine.

Bridgeport VMC3020

With huge magnifying glasses over his regular glasses he would manually turn cranks to machine any number of precision parts. There was no digital read-out. Every shop you went into had a Bridgeport milling machine. Bridgeport set the standard back then.

Things have changed. Today Bridgeport provides sophisticated 5 axis CNC machines like their XR500 5 axis milling machine. HST repairs the spindles that go into these machines.

Today’s machines make parts faster and to tighter tolerances. Gone is the skilled machinist setting dials and turning hand cranks to mill away a few thousands at a time in straight lines. Now a programmer is setting complex tool paths on multiple axis with automatic tool changes; a whole new skill set.

But when the programmer makes a mistake or a part isn’t properly located…crash. That’s when you are glad you know about HST. We repair Bridgeport spindles.

Spindles on older Bridgeports only ran when the machinist was operating them. Spindles on today’s machines may not stop for days at a time; even running “lights-out”. This is another good reason to use HST to repair your Bridgeport spindle.

Spindles on older Bridgeports only ran when the machinist was operating them. Spindles on today’s machines may not stop for days at a time; even running “lights-out”. This is another good reason to use HST to repair your Bridgeport spindle.

We will restore your worn or damaged Bridgeport spindle to factory new condition. We only use top name brand super precision ABEC 7 spindle bearings. Journals are restored to micron tolerances, rotating components are precision balanced, tool interface surfaces are restored to original run-out tolerances; in short you spindle will be as good as new.

Bridgeport has been a leader in the machine tool industry since 1938.

When Bridgeport introduced their Series I Standard, a milling machine with a revolving turret that moved the head from one end of the table to the other, it revolutionized the machining industry. This machine, offered unheard of productivity and versatility at a price that every machine shop could afford.

Over the years, Bridgeport has continued to set the standard for milling machines, as well as expanding to provide many more machining solutions. The Bridgeport name is known and respected worldwide. For over 3 decades HST has set the standard for spindle repair. Some things don’t change.