Broken or Damaged Tips

HST has developed a proprietary method for repairing broken tips and damaged tapers on dicing spindles. Our process restores your damaged spindle to OEM like new condition.

Our 6 step repair process can save you thousands of dollars by repairing a spindle rather than replacing it. The spindle will be precision balanced and run like new.

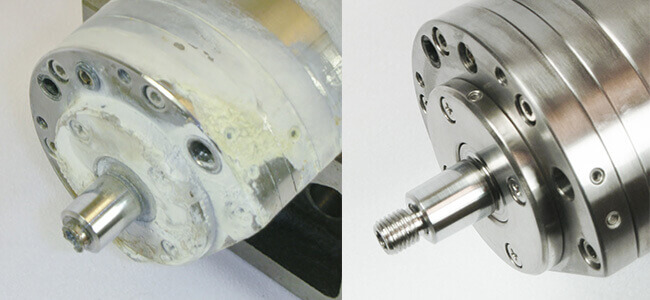

Below is a typical example of a broken tip repair.

Left Photo: Dicing spindle with a broken tip.

Right Photo: Dicing spindle with a repaired tip.

The front end of a spindle is super critical. To accurately dice wafers or slice other material the spindle must operate with sub-micron tolerances. HST has developed a repair technic and grinding capabilities to meet or exceed those demanding tolerances.

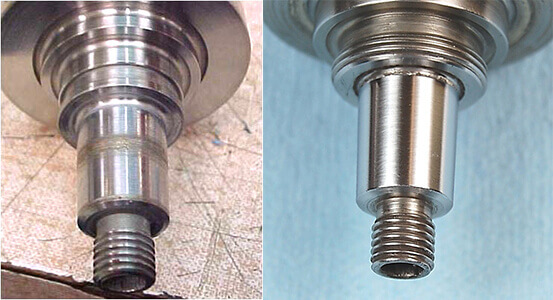

Worn or damaged shaft tapers can result in unacceptable cuts, large kerfs and fracturing along the edge of the cut. A perfect taper is absolutely necessary for a perfect cut or slice. HST has developed a 3 step process we call GPG to perfectly restore your taper surfaces.

Left Photo: Typical taper damage.

Right Photo: A typical taper repair damage using our GPG process..