Corroded Coolant Jackets

High Speed Technologies, Inc. can repair damaged air bearing spindles that are used in dicing and back grinding. A common cause of failure on these spindles is coolant leakage through the motor coolant jacket.

Because most dicing spindles are rather compact the motors require water cooling. Often dicing facilities use the same DI water to cool the motors that they use in their cutting process. DI water is very aggressive toward certain metals and can actually dissolve them.

Eventually the water jacket will begin to leak coolant into the spindle. When this happens imminent spindle failure is on hand. Once a leak is propagated the spindle can fail in several ways usually with a radial crash. If the leak remains the water can propagate into the electronics or motor windings and cause extensive damage.

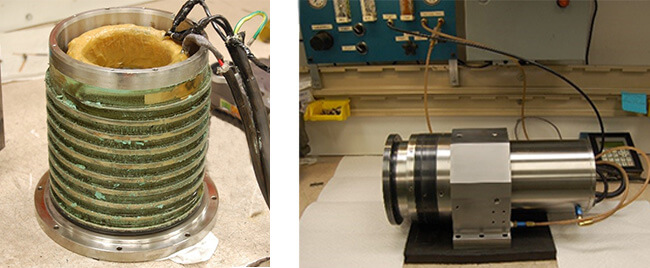

Water can leak through partially dissolved coolant jackets. DI water can dissolve metal jackets.

On the other side of the coin some facilities use water that contains contaminates that can build up on the coolant jacket that can restrict or even completely clog the water flow. Contaminates in the coolant fluid can also deposit scale on the coolant jacket. This reduces the ability of the jacket to remove heat from the motor windings. Scale build up or restrictions in the coolant jacket can result in a motor failure from overheating. At HST we always remove and clean the coolant jacket. With every spindle rebuild all components are thoroughly cleaned and inspected. They must pass our stringent QA process. But sometimes they don’t. What then?

We don’t know what this green stuff is. But it shouldn’t be there.

HST will make a new water jacket when the original one is beyond repair.

When a part such as the water jacket shown above is too far gone, HST can manufacture a new one.

When we receive a dicing, back grinding or other air bearing spindle we go over every inch of the spindle. All parts will be meticulously cleaned. Bad parts are replaced with new. Your spindle comes back with OEM performance and a full guaranty.

To get an estimate, just fill out the form or call 1-603-438-0333 Monday – Friday 8 a.m.-4:30 p.m. ET.