Disco Backgrinder BG-89-0077-A Spindle Repair & Rebuild

This Disco Backgrinder BG-89-0077-A arrived at our facility via expedited freight. This typically means one thing; the customer needs it back right away. So, we got right to it. Upon disassembly, we noted damage to the outer Axial thrust bearing. Internally the spindle was very clean and there were no indications of a crash or excessive feed rate. A phone call to the customer revealed that they had experienced a sudden loss of air at their facility while the spindle was operating. Without air, the rotating shaft made contact with the outer thrust bearing and damaged it. We ground the thrust bearing flat to remove the damage and machined a new air groove. We also repaired the thrust surface on the shaft. This restored the spindles axial lift capacity.

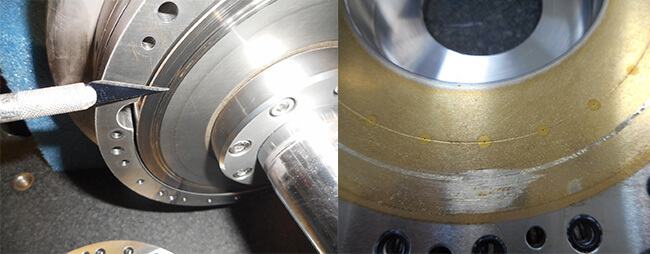

Shaft thrust surface made contact with the outer axial.

Unfortunately, the stator for this spindle is integral to the machine so we could not test run it electrically. To get around this problem we manufactured tooling which allowed us to belt run the spindle vertically to operating speed. Upon final testing, the taper OD had less than 1 micron of runout and the spindle ran like new at .006 in/s. This spindle was on its way back to the customer in less than 5 days.

For your Disco Backgrinder spindle repair call High Speed Technologies today 1-603-483-0333 or email us at [email protected]!