Disco DFG-82/IF Spindle Repair & Rebuild

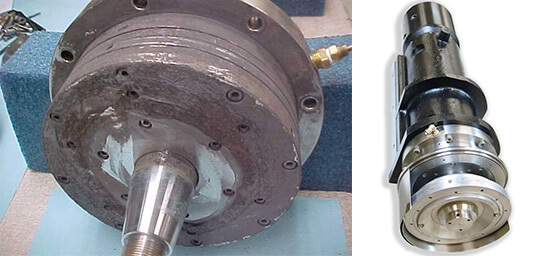

Two of these Disco DFG-82/IF Backgrinder spindles came in as a pair. The first spindle was in pretty rough shape. Prior to disassembly we pressurized the coolant circuit and found evidence of an internal coolant leak. Before the spindle even came apart though we had to Mfg. a special tool to remove the tool hub without damaging it or the spindle shaft. Once the spindle was dismantled we were able to verify the internal coolant leak and its origin. Several of the coolant plugs within the housing OD had failed allowing coolant to seep by and into the spindle. We tapped the ports and replaced all existing plugs with new stainless steel threaded plugs with sealant. After proving the new plugs held pressure, we rebuilt the spindle. Of course all bearings were reworked as needed and all other seals were replaced with new. It was then balanced at operating speed and performance tested. The spindles stator housing was painted with a Hi-Solid two part epoxy and the spindle was prepared for shipment. It looked and ran like new!

Left Photo: Rusted thrust surface.

Middle Photo: Failed housing plug.

Right Photo: Tool Hub.

The second of the two Disco DFG-82/IF Backgrinding spindles initially passed some testing. However, the stator was suspect due to moisture contamination. The stator was hand delivered to a third party vendor for wash, bake and surge test just to be sure. While the stator was out for service we proceeded with our analysis. The internal coolant leak was in multiple locations. One of the coolant jacket O-rings and two of the housings coolant plugs had failed allowing significant amounts of coolant to leak into the spindle. Unfortunately the liquid contamination caused the rotating shaft to make contact with the Radial bearing ID and damage it. After reworking the Radial bearing, replacing all housing coolant plugs and receiving the good news that the stator was in good order, we rebuilt the spindle. Upon repair and testing this Backgrinder ran beautiful at .006 in/s.

Left Photo: Rust build-up on internal parts.

Middle Photo: All ten coolant plugs were replaced.

Right Photo: Stator: washed, baked and surge tested.

If you have a Disco DFG-82/IF spindle in need of repair, call High Speed Technologies today 1-603-483-0333 or email us at [email protected]! We would love to answer any of your questions.