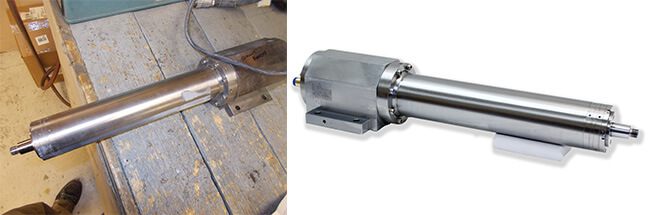

Disco NCP00043 Spindle Repair & Rebuild

The reason the customer sent in this Disco NCP00043 spindle was literally written all over it: “Coolant blocked.”

Indications of internal coolant leak on the thrust bearings and spacer

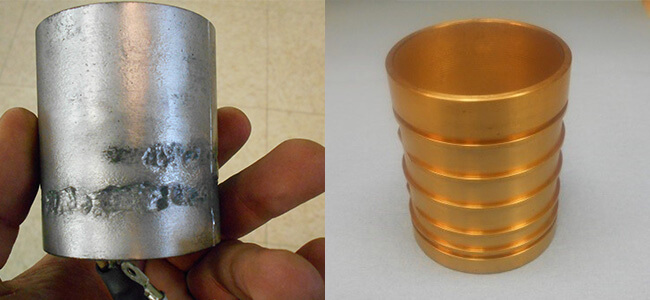

There are a couple of things that can prevent the free-flow of coolant through a spindle such as this. But upon disassembly the problem was clear. The coolant pathways were completely blocked with contamination and rust. This was not the only problem however. The stator jacket was also corroded through in several areas which led to an internal coolant leak. The corrosion also reached the stator. Upon speaking with our customer, we learned that they use Deionized (DI) water. DI Water is often used in the semiconductor industry. It has its positive attributes of course but the lack of ions in this coolant makes it unusually corrosive. We could not save the existing coolant jacket so we replaced it with a new one that we manufactured in our own machine shop.

Left Photo: Coolant jacket before cleaning: The contaminant obstructing the free flow of coolant looked like mud!

Right Photo: Coolant jacket after cleaning: Cleaning the coolant jacket revealed another problem. Corrosion!

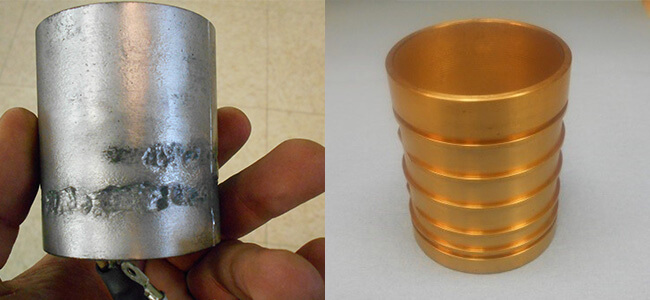

Left Photo: Stator: The stator had to be pressed out of the jacket. The stator sleeve was in need of repair but the stator was ok.

Right Photo: New Stator Jacket: We mfg this new stator jacket in our very own machine shop.

Left Photo: Stator: The stator had to be pressed out of the jacket. The stator sleeve was in need of repair but the stator was ok.

Right Photo: New Stator Jacket: We mfg this new stator jacket in our very own machine shop.

Along with replacing the coolant jacket, we also replaced all of the O-rings, stainless steel screws and carbon brushes. Upon repair and with some final balancing the spindle ran like new .0023 in/s at 30,000 RPM. Here at High Speed Technologies we know a down spindle is down production. So call us today with you Disco NCP00043 spindle repair questions, or email us [email protected].