Mazak FH Series Spindle Repair & Rebuild

Mazak FH Series Spindle Repair & Rebuild

HST provides Mazak FH Series Spindle Repair and Rebuild to like new condition and we warranty our repairs for one year. Mazak FH horizontal machining centers come in a broad spectrum of capacities. These are a robust horizontal mill.

Mazak FH 6800 spindle before and after repair

Besides not working, this Mazak FH 6800 spindle arrived in pretty ugly condition. When we shipped it back to the customer the spindle not only performed like new, it shined.

When we repair an oil mist system all lubrication lines are replaced and the jets are carefully cleaned and inspected. We provide plenty of extra line for field trimming to proper length.

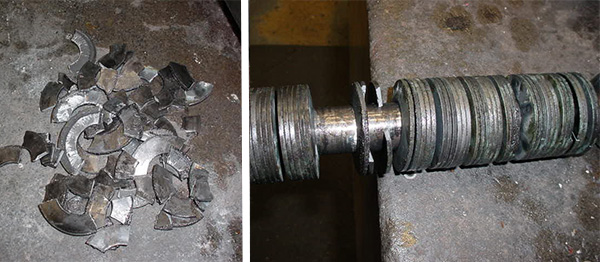

Drawbar springs have a limited operational life.

Replacing all Belleville springs is part of our base repair service.

Belleville springs fatigue failure

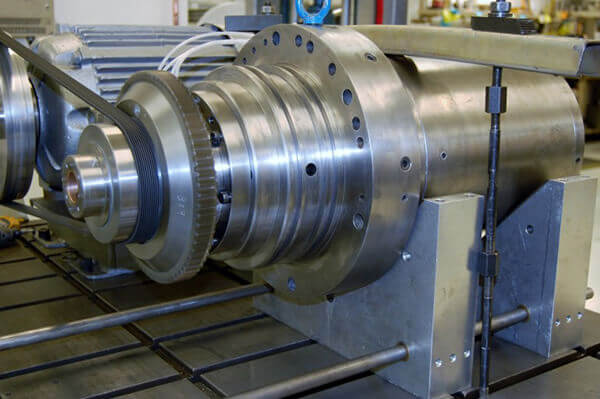

Before any spindle is assembled all components are thoroughly inspected and meticulously cleaned. Any damaged our out of spec parts are repaired or replaced. The spindles are assembled in our climate controlled clean room area. A little contamination can cause a premature failure.

Mazak FH 6800 ready for assembly

At HST we only use top name brand ABEC 7 super precision spindle bearings purchased from authorized distributors.

Setting the rear roller requires micron measurements and an experienced hand. Even with precision equipment for measuring the rear roller must feel “just right” once it is set. That’s where the years of experience pays off for our customers.

Setting pre-load on a roller bearing

Before shipping your spindle must pass exhaustive testing. On the right is a Mazak FH-6800 on our test bench. The spindle will be instrumented for vibration, temperature and balance. After run-in the spindle must pass our stringent test criteria at full speed.

Mazak FH6800 on our test bench

At HST we precision grind bearing spacers and hand lap them to micron tolerances every day. This is just another reason to trust HST with your Mazak spindle repair.

- OEM precision

- OEM Warranty

- Top name brand bearings

- Fast Turnaround

- Free quotes

- Not OEM pricing

Have a question? Give us a call. We’ll answer the phone. Or email us.

1-603-483-0333

[email protected]