Mazak FJV Series Spindle Repair & Rebuild

Mazak FJV-25

Mazak FJV-25

Mazak machines in general are well known for their machining excellence. The FJV series is especially noteworthy for its precision and productivity. With more 30 years of experience, we at High Speed Technologies know Mazak spindle repair!

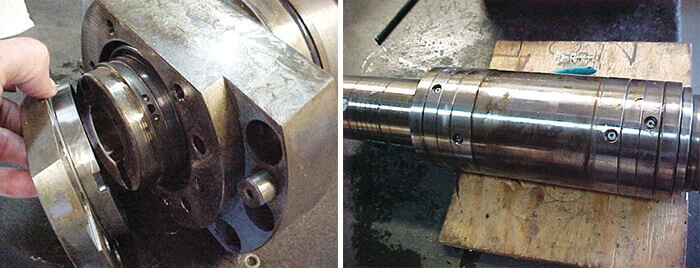

Left Photo: Removal of front cover of a Mazak FJV-25.

Right Photo: Shaft & bearing stack.

Manufactured in the late 1990’s this spindle has cut a lot of chips. And it was doing so until our customer, a small machine shop out of British Columbia Canada began having tool holding issues. After replacing the drawbar springs and modifying their retention knobs no longer solved their issues, they sent the spindle in to HST.

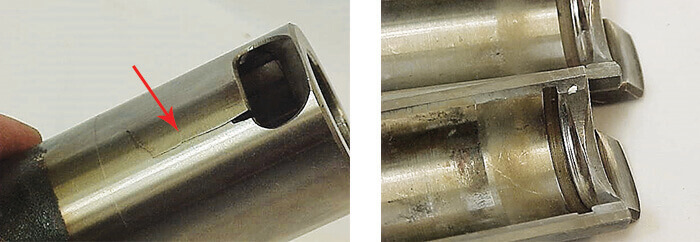

Upon receipt, the reason for their tool holding issues was immediately clear to our team. The Gripper Sleeve that houses the fingers was cracked in two locations. Amongst other problems, this was directly resulting in zero draw force. The gripper fingers were also worn and this contributed to the problem.

Left Photo: Cracked gripper sleeve on a Mazak FJV-25.

Right Photo: Worn gripper fingers.

During our evaluation we found other problems which were not tool related. The bearings were very worn and the shafts taper ID had excessive runout at 40 Micron! We replaced all bearings with new ABEC7 NSK super precision bearings and restored the 40 taper to new condition with our in house Grind-Plate-Grind process. Of course all seals were also replaced with brand new chemical resistant seals.

When the repairs were complete the spindle ran like new with plenty of draw force and 1 micron runout at the end of our 300 MM certified test bar. We were even able to re-use the customers drawbar springs which had only seen 30 days of cycles, saving them hundreds of dollars. At HST quality is always #1, but we also understand that every dollar counts. If there is still life in a wear item and the customer wants us to re-use it, we do so.

If you’re Mazak FJV is having tool holding issues or low draw force, feel free to send it in for a Free No Obligation Evaluation. At High Speed Technologies our experienced technicians are here to help you with your Mazak spindle repair needs! Or if you simply have a Mazak spindle question, give us a call today 1-603-483-0333. It doesn’t cost anything to consult with our technical crew!

Mazak FJV-35/60

The Mazak FJV 35/60 is a high end, high speed oil lubricated spindle designed for peak production.

When our customer, an injection and plastic mold industry leader, sent their Mazak FJV 35/60 spindle in for evaluation, it was because it started to get noisy and they were rightly concerned. We can understand why. Prior to disassembly, when the shaft was rotated by hand the bearings sounded very loud and “scratchy.”

Once the spindle was dismantled we could see the main cause of failure fairly quickly. The oil bearing lubrication within the front bearings had been completely washed with what appeared to be coolant. Unfortunately the coolant also brought with it cutting particulate and this combined contamination damaged the bearings to the point where their damage became very audible to the customer.

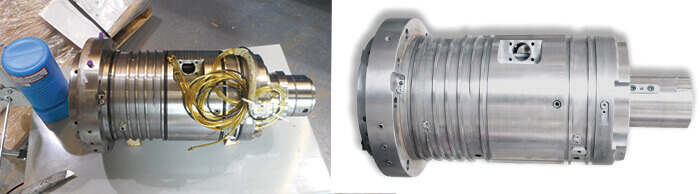

Left Photo: Coolant observed inside of the spindle housing of a Mazak FJV 35/60.

Middle Photo: Coolant within bearings #1 & #2.

Right Photo: Drawbar Springs replaced with new.

This Mazak spindle repair was very involved but went well. Our experienced spindle repair technicians returned the spindle to new condition at a fraction of the cost of a replacement spindle from the OEM. And as with all oil Mazak spindle repairs, we replaced all oil lines, ferrules and compression sleeves with new. It not only looks good but it reduces the opportunity for bearing contamination upon re-installation into the customer’s machine.

Out with the old tubes…In with the new oil tubing w/ ferrules on a Mazak FJV 35/60.

At High Speed Technologies we go the extra mile for each Mazak spindle repair. If your spindle has become noticeably louder, please give us a call. Our experienced team will be happy to speak with you about it 1-603-483-0333. Or just send it in today for a Free, No Obligation quotation.