Matsuura Spindle Repair & Rebuild

Your Matsuura spindle is in expert hands with the factory-trained, Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of Matsuura spindles to original factory performance. Need it fast? We can repair your spindle within three days of customer approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are some common Matsuura spindle performance issues that we resolve:

- Noisy or contaminated bearings

- Increased vibration

- Chatter marks

- Blunt force trauma

- Burned stator

- Fatigued springs

- Poor part finish

- Failed seal

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will include replacing or restoring all worn drawbar springs, seals and critical surfaces. Then we perform high-speed balancing to eliminate vibration, extend life and improve part quality. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986.

Featured Repairs

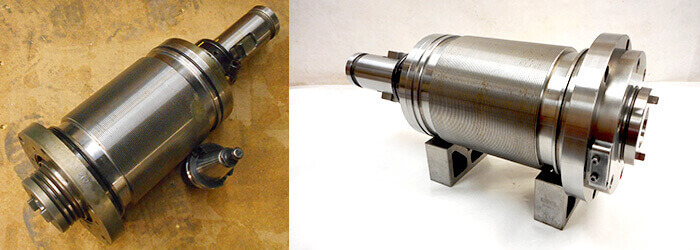

Job: I1338

The above Matsuura spindle arrived to us seized hard. The customer stated it had been making an unusual noise prior to its failure. Upon disassembly we found that all bearings had been severely contaminated with cutting particulate and fluid, however the rear roller bearing cage had disintegrated causing the shaft to seize. The unusual noise the customer had noted was the rear bearings imminent failure. The seizure of the shaft resulted in damage to the rear bearing spacer, which had to be remanufactured. All bearings and seals were replaced with new and we replaced all Drawbar components with new as well.

Left photo: Shaft taper ID will require a kiss grind.

Middle photo: Failed rear roller bearing!

Right photo: Bearings dry & contaminated!

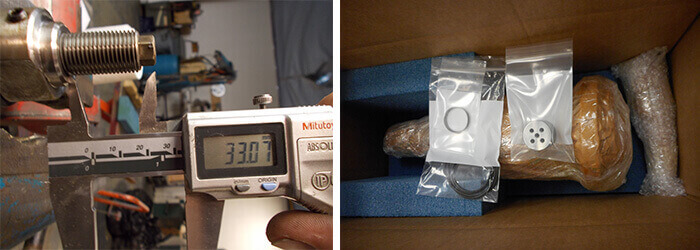

While analyzing the shaft in detail in our metrology room, we also found that the rear shaft OD was slightly bent. We were able to eliminate this runout completely by adjusting the rear shaft nut in assembly. There was moderate runout measured at the taper ID as well which translated to severe runout at the end of our test bar. But after kiss grinding this surface on our in-house Kellenberger Universal Grinder, we were able to reduce the runout to 10+ microns at the end of the test bar, which is within acceptable limits. This spindle was running like new when it left our facility. The spindle was nicely packaged for shipping to ensure safe travel to its destination.

Left photo: Measuring for Drawbar adjustment.

Right photo: Ready to ship!

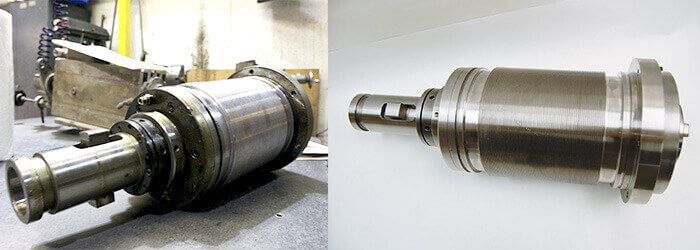

Job: I0661

This Matsuura spindle began to run hot and the shaft bound up while making a cut. However, when the spindle was shut down and had time to cool off, the shaft freed up. Upon evaluation of the spindle, it was clear that the spindle had been in operation for a while. The grease lubrication within each bearing had completely degraded causing them to overheat when the spindle was operated at higher RPM’s for extended periods of time. This excessive heat caused rotating components to lock up on the labyrinth cover ID. The inner spacer also spun free on the shaft causing damage to the spacer and the shafts bearing shoulder. We manufactured a new spacer in our machine shop and kiss ground the shaft shoulder on our universal grinder.

Left photo: All bearings dry and worn!

Middle photo: Inner spacer damaged!

Right photo: Precision gripper balls were replaced with new.

The rebuild of this spindle went very well. Having rebuilt many Matsuura MC-510 spindles we expected as much, but not all spindles cooperate as well as this one did. Runout at the end of our test bar was 10 micron, the drawbar pull force was set back to factory spec and the spindle ran extremely well with Velocity measuring at a mere .0111 in/s and Acceleration of .2710 g at the end of a 12 hour run in period. As far as we know this spindle is still in operation, cutting chips for our customer who is an east coast Precision Machining specialist.

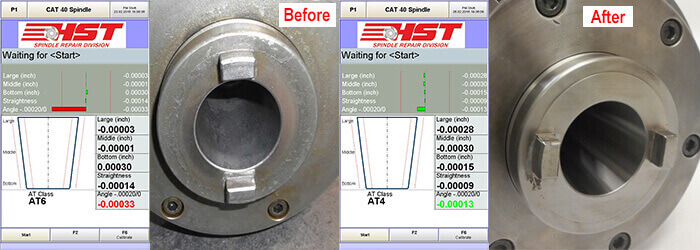

Job: I1730

Our customer explained to us that their Matsuura spindle (above) seized suddenly after it began making a lot of noise. Once we removed the shaft and bearing stack from the spindles main housing it was evident why it had seized. Its rear roller bearing had failed catastrophically. Because of the extent of the bearing failure we were not able to determine the exact reason for failure, but it had all of the indicators of lubrication failure. Heavy fretting was also observed on bearing #1 as well as some rusty particulate.

Although the runout measured at the shafts CAT40 Taper ID was acceptable, the contact between the tool and shaft taper was poor. The CAT40 Taper angle failed our certified air gauge test as well but we were able to restore the contact angle with an in house kiss grind. The shaft taper wasn’t very far out of tolerance but we were happy to return it to industry standard. Results can be seen below.

After kiss grinding the shaft taper we began the rebuild right away. The spindle ran excellent during the 4 hour bearing run in period. Not all spindle bearings break in that quickly. Much depends on the bearings, the required lubrication quantity and spindle max operating speed. Please click on this link for further information regarding bearing lubrication and break in period: What-lubrication-should-I-use.

At the end of the 4 hour period we trim balanced the spindle and performed final testing. The runout at the end of the test bar was excellent at 1 micron and drawbar pull force was restored to 1,500 Lbs (+). The spindle also ran like new (.014 in/s) and was ready for installation and operation. With most spindles we perform the bearing break in procedure which can save our customers several hours of time.

All spindles go through meticulous testing before being shipped back to the customer. We know a down spindle is down production, that’s why we offer QTA. With QTA service you’ll have your spindle back in no time. So if you have a Matsuura spindle that is down don’t hesitate to call today with your spindle repair and rebuild questions!

1-603-483-0333