Mori Seiki MH Series Spindle Repair

High Speed Technologies, Inc. provides expert Mori Seiki MH Series Spindle Repair and Rebuild. Call 1-603-483-0333. We will replace bad, worn and damaged bearings with top name brand super precision ABEC 7 spindle bearings. We can restore damaged or crashed shafts and restore worn tapers to like new condition. HST has specialized in spindle repair for over 30 years. We can also provide emergency repair for your Mori MH-63 spindle.

High Speed Technologies, Inc. provides expert Mori Seiki MH Series Spindle Repair and Rebuild. Call 1-603-483-0333. We will replace bad, worn and damaged bearings with top name brand super precision ABEC 7 spindle bearings. We can restore damaged or crashed shafts and restore worn tapers to like new condition. HST has specialized in spindle repair for over 30 years. We can also provide emergency repair for your Mori MH-63 spindle.

Our repairs all come with an OEM equivalent warranty. We also provide free damage evaluation and forensic analysis. Our technicians have trained at various OEM facilities and hold certificates in skill sets such as balancing and vibration analysis. If you want expert repair, OEM warranty, and fast turnaround without the cost of an OEM repair call HST at 1-603-483-0333.

The MH-63 is a rugged horizontal milling machine. Like most Mories, this spindle is oil-mist lubricated. Being oil lubricated there are certain nuances that the technicians must know about, that is where our years of experience pay off. We know these spindles inside out. Your spindle performance will be restored to new condition.

Mori’s MH 63 is a robust horizontal mill spindle

Some Featured Repairs

Mori Seiki Spindle Repair Job I-8637

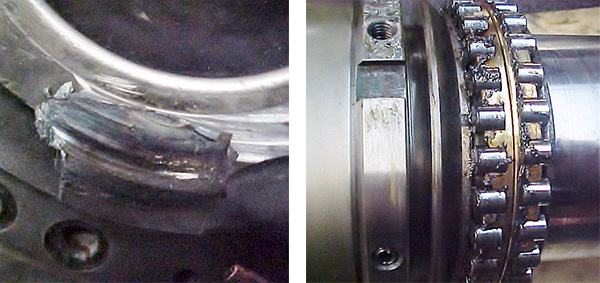

This Mori Seiki MH-63 spindle needed major repair after a hard crash. We found the shaft run-out to be 10µm on the taper face. The drive dogs were badly damaged. However, even if the spindle wasn’t crashed, the bearings were not going to last much longer. Our inspection discovered that this MH-63 had a badly contaminated roller bearing. It was certainly on its last legs.

We restored the damaged taper with our GPG process. The gouged out drive dog area was repaired with micro welding and re-machining. New hardened drive dogs were fabricated. All of the minute oil passages and metering orifices were thoroughly cleaned and checked. Each lubrication jet was meticulously cleaned.

The spindle performance was great when completed; assembled run-out less than 2µm determined by our certified 300MM test bar, vibration readings 0.03397 in/sec and pull force of 3500 lbs.

Mori Seiki Spindle Repair Job I-9039

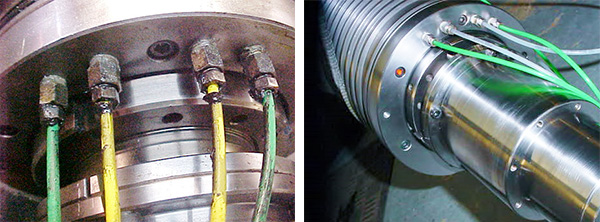

We received this Mori MH-63 with damaged drive dogs. The taper had over 4µm of run-out and was in pretty rough condition. These are all indications of a crash. The customer asked us to modify the shaft for removable drive dogs.

Our inspection found moderate contamination in the roller bearing. As always, all bearings were replaced with top name brand ABEC 7 Super Precision spindle bearings. And even though no Belleville springs were broken, it is our policy to always replace them.

Just before shipping this Mori MH 63 had great numbers. Measured run-out was less than 2µm. The vibration reading was 0.03570 in/sec and pull force of 3570 lbs.

With new drive dogs the spindle is tested to maximum RPM.

The damaged drive dogs were cut off and new sockets are machined and ready for custom made hardened drive dogs.

HST Job # I-9636

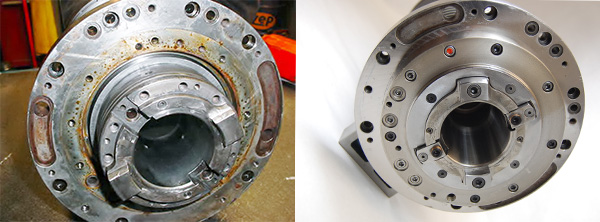

Besides a complete rebuild the customer wanted us to give special attention to the drawbar pull force. They also requested us to modify the shaft for removable drive dogs.

Preliminary check indicated that the bearings were very close to complete failure. However, the drawbar pull force was at 3310 Lbs; a little low, but still within serviceable limits.

Like every spindle repair we replaced worn bearings and repair damaged tapers. We can even repair a spindle shaft with major damage. We replaced all of the drawbar springs and got the pull force up to 3660 lbs.

Here is the completely rebuilt Mori Seiki MH-63 spindle before repair and after with new removable drive dogs.

When we shipped this Mori Seiki MH-63 the spindle was ready for more years of production. Using our certified 300MM test bar, run-out at the taper was measured less than 2µm and the front velocity vibration readings were 0.02615. Excellent!

At HST we repair all make and models of Mori Seiki spindles. We will only use top name brand ABEC 7 super precision spindle bearing in your repair. So if you have a problem give us a call 1-603-483-0333. Anytime during business hours we’ll answer the phone.