Miyano Spindle Repair & Rebuild

Since its inception in the 1920’s, Miyano has been well known for their CNC automatic lathes. Recently purchased by Citizen Machinery Co., Miyano is still well respected in the industry. Being in the spindle repair business for the past 30 Years, High Speed Technologies knows Miyano spindle Repairs and Rebuilds. We have the experience to fix your spindle and the test equipment to make sure it’s done right the first time. All of our Miyano spindle repairs come with a one-year warranty. Call today for your Miyano spindle repair questions 1-603-483-0333.

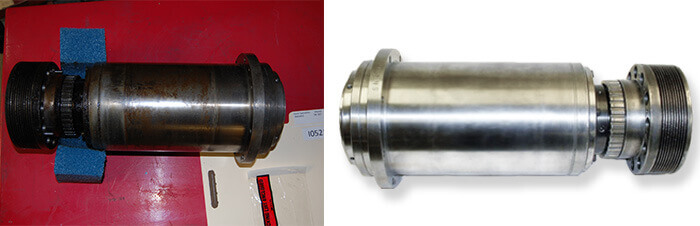

When our customer, a small machine shop on the east coast, sent us their Miyano BND34S3 CNC Lathe spindle it was in very poor condition. The customer’s complaint was “Not holding tolerance. Bad finish. Noisy but seems to spin too freely.” Being a small machine shop, this one spindle failure was very painful to our customer. So we made their spindle repair a priority and moved quickly.

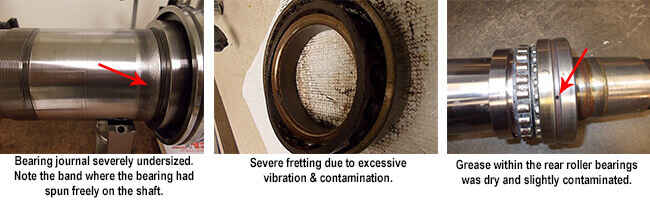

After disassembling the spindle, a couple of things stood out right away. The #1 bearing had been spinning freely on the shaft for some time. This damaged both the bearing and the shaft. The shaft journal now measuring -59 microns undersized required G-P-G. This acronym stands for Grind-Plate-Grind. This is our process for restoring damaged tapers or bearing journals on a spindle shaft or housing bore. The shafts front shoulder was also damaged and required a Kiss Grind only. Also referred to as a “breeze grind” or a “dust grind” this is a light surface grind that will remove minor surface damage or excessive runout.

Also, severe fretting was observed on the entire bearing stack. This was a clear indication of significant vibration and some contamination. This excessive vibration is what lead to the customers “bad finish.” On the plus side, both the main pulley and timing pulling were verified in good condition!

After restoring the shaft to new condition we replaced all bearings with top of the line ABEC 7 bearings and put the spindle through a series of rigorous tests on our test bench. The shaft ran true at less than a micron on the taper. We ran the spindle for nearly an entire day in order to break the heat in the rear taper bore roller bearing. This ensured that the spindle was ready for immediate operation upon install into the customer’s machine.

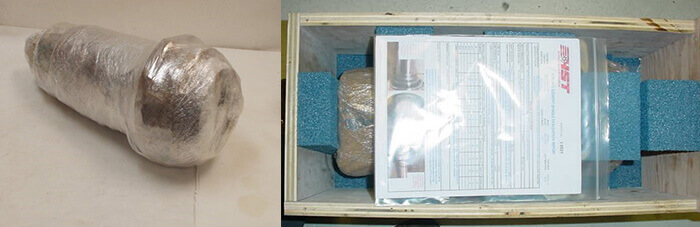

After the repair and testing was complete, the spindle was wrapped tightly in anti-rust paper and cellophane and safely packaged for expedited transport back to our customer who was eager to put the spindle back into production. This repair was completed over two years ago and the spindle is still in operation today!

Whether you’re a large company with hundreds of machines or a small machine shop cutting chips, you can be confident that your Miyano spindle will be repaired to the highest standards. High Speed Technologies knows Miyano spindle repair! Call today 1-603-483-0333.