Mori Seiki MV Series Spindle Repair

At High Speed Technologies, Inc. we provide expert Mori Seiki MV Series Spindle Repair and rebuild. Call 1-603-483-0333. We have over 30 years of experience with Mori Seiki spindles and offer a full warranty with every repair. Our turnaround time is short and our repairs are OEM quality.

At High Speed Technologies, Inc. we provide expert Mori Seiki MV Series Spindle Repair and rebuild. Call 1-603-483-0333. We have over 30 years of experience with Mori Seiki spindles and offer a full warranty with every repair. Our turnaround time is short and our repairs are OEM quality.

Like most Mori Seiki spindles the MV series spindles are oil injection lubricated. The MV series spindles are a very rugged vertical mill and again like all Mories they have their own nuances. Mories maximize spindle rigidity by using long bearing spacers. To maximize bearing life these spacers must be ground to equal lengths within micron tolerances. At HST we do that every day. We live in a micron tolerance work environment. Additionally these spacers have small orifices that direct lubrication oil to different areas. They must be perfectly clean and proper alignment is critical. At HST we take extraordinary care to make sure every Morie Seiki spindle that we repair is precisely assembled to OEM standards.

We usually receive the spindle cartridge from MV machines. This will include the stator and allows us to run the spindle up to full speed with the spindle motor.

We will repair your Mori Seiki spindle to OEM new performance with an OEM equivalent warranty. But you won’t pay OEM prices.

Extra-long spacers give Mori Seiki stiffness. Each spacer set must be exactly the same length to avoid over stressing the bearings. To achieve micron precision each spacer set is finished by hand lapping. Note the tiny orifice for directing lubrication to the bearings. If these aren’t perfectly clear premature bearing failure is guaranteed.

Some Featured Repairs

Mori Seiki MV-40

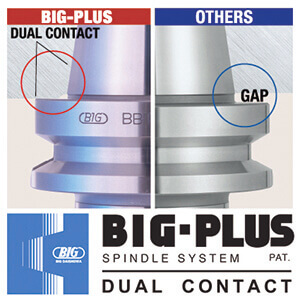

Ceramic taper inserts provide a very hard and durable surface. So this type of insert is offered on a variety of high end machine manufacturers.

But, somehow our customer managed to destroy the insert on this Mori Seiki MV-40 spindle. We can replace the ceramic if asked to. However, this customer was very unhappy with the ceramic and requested that we install a hardened steel insert.

On the left is the MV-40 with most of the ceramic insert missing. On the right is the same shaft with a hardened steel insert.

Mori Seiki MV-45

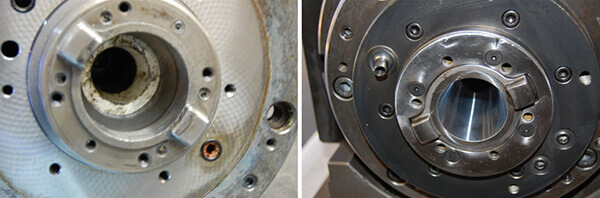

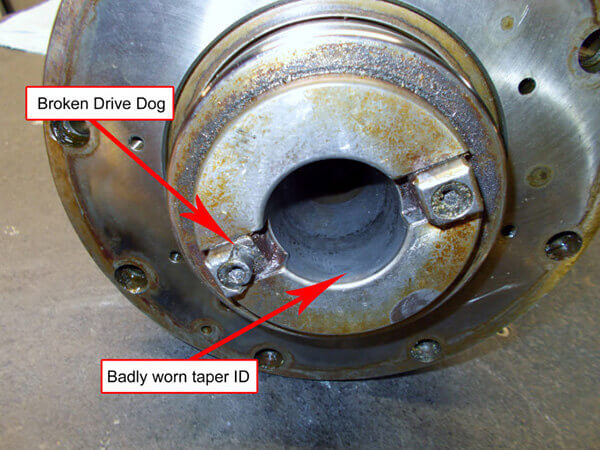

This spindle off of a Mori MV- 45 machine came in with a broken drive dog. We measured a whopping 20 µm run out on the taper ID. It had clearly been well used.

Things took a turn for the worse when we examined the bearings and shaft.

Although the bearings were not in terrible shape they had the unmistakable brown film that results from fretting.

Fretting is caused by a loose fit. So we were not surprised to find the shaft measured 7 µm under size.

We manufactured a new hardened drive dog. The shaft journal surfaces were restored to ISO specifications and the spindle received one of our comprehensive rebuilds. The run-out at the taper after rebuild was 1 µm.

This Mori Seiki MV 45 spindle is back to factory new condition.

We only use Top Name Brand ABEC 7 Super Precision spindle bearings.