Mori Seiki NH 4000 & 5000 Series Spindle Repair

At High Speed Technologies, Inc. your Mori Seiki NH series spindle is in expert hands.

At High Speed Technologies, Inc. your Mori Seiki NH series spindle is in expert hands.

These excellent high-speed horizontal spindles have their own nuances. At HST we know all of them. For instance, the spacers have small orifices that direct lubrication oil to different areas. These must be properly aligned to allow oil to reach the bearings. At HST we take extraordinary care cleaning each orifice and lubrication passage. With Mori Seiki NH series spindles, the journal for the rear bearing stays with the housing. We always provide a new rear roller bearing and set the preload. This makes life for the installation technician much easier.

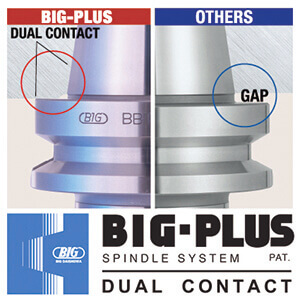

We have 30 years of experience rebuilding Mori Seiki spindles and offer a full warranty with every repair. The factory-trained, Big Plus–certified technicians at High Speed Technologies, Inc have repaired dozens of oil-injection lubricated, Mori Seiki NH series spindles to original factory performance. Need it fast? We can repair your spindle within three days of estimate approval, and offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Examples of Mori Seiki NH Spindle Repairs

One of our regular customers crashed their Mori Seiki NH 4000 spindle so hard they cracked the shaft. A new shaft from Mori Seiki was many weeks away. HST had the spindle up and running in less than 2 weeks.

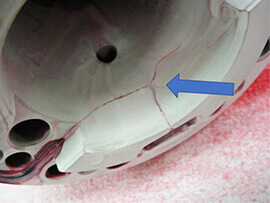

The die penetrant clearly shows the hairline cracks in the spindle shaft. Careful preparation and precision micro welding was next.

This is how it looked after the repair. The spindle was back in production in two weeks instead of two months and for a fraction of the cost. How’s it working? It’s been in regular production for almost two years. If you have a Mori Seiki NH spindle with a damaged shaft or if you need emergency repair service please give us a call.

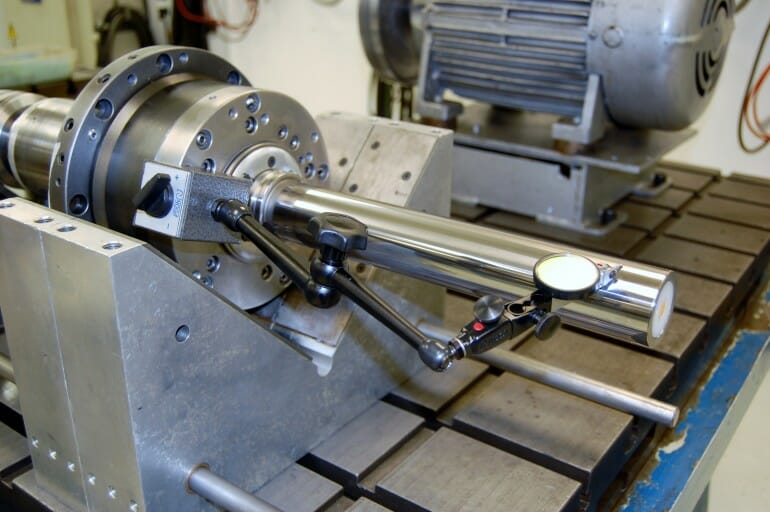

We received another Mori Seiki NH 4000 spindle from a customer who told us the spindle was producing very poor part quality. After we looked at the taper we were not surprised. Very poor tool contact and high spots let the tool rock inside the taper. Before the repair we measured 165 µm (0.0065”) run-out at the end of our test bar.

Authorized BIG PLUS repair

We are unsure who removed this spindle. However, there were several deep gouges on different surfaces. These must be corrected to eliminate leak paths and difficulty during re-assembly. Qualified technicians should be used to remove a spindle and prevent additional damage.

The shaft was repaired with GPG, the gouges repaired and the spindle was rebuilt using NSK Super Precision Spindle bearings. How did the repair go? Vibration numbers were very good and the run-out at the end of the test bar was measured at 0.2µm (0.00008”) !! This is one of the reasons that we love Mori Seiki spindles, stout, well made and super performance.

Got a problem with bad part finish? We can help just give us a call.

When we first received this spindle it had 165 µm of run-out at the end of the test bar. After GPG and the installation of new ABEC 7 bearings the run-out measured 2µm ! OEM pass criteria is 8µm.