Mori Seiki NL Spindle Repair and Rebuild

The Mori Seiki NL class of spindle is very likely Mori’s most popular lathe to date. Whether it’s the NL1500, NL2000, NL2500 or the NL3000, your Mori Seiki NL spindle is in expert hands with the Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of Mori Seiki NL spindles to original factory performance. Need it fast? We can repair your spindle within three days of customer approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

The Mori Seiki NL class of spindle is very likely Mori’s most popular lathe to date. Whether it’s the NL1500, NL2000, NL2500 or the NL3000, your Mori Seiki NL spindle is in expert hands with the Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of Mori Seiki NL spindles to original factory performance. Need it fast? We can repair your spindle within three days of customer approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are just some common Mori Seiki NL spindle performance issues that we resolve:

- Noisy or contaminated bearings

- Increased vibration

- Shaft damage from spindle crash

- Shaft taper runout

- Poor part finish

- Failed seal

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will also include replacing seals and restoring critical surfaces. Then we perform high-speed balancing to eliminate vibration, extend life and improve part quality. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986

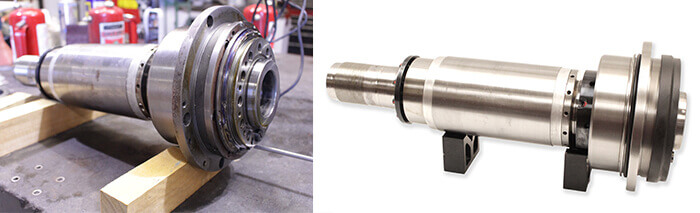

When this Mori Seiki NL2500 spindle arrived to us there were definite indications of a spindle crash. Sure enough our customer explained that 8 years ago they had crashed the spindle and removed it from operation. And there it sat for almost a decade until they needed it. And that’s when they contacted us.

Immediately upon evaluation we could see that the flange was severely damaged and would need to be replaced. Working closely with the customer we were able to acquire a new flange. There was also significant damage to the shafts work end where it made sudden contact with the table. Our capable in house machine shop was able to repair the damaged portion of the shaft so that it could accept the new flange. The lubrication that remained within each bearing was indicative of a long life. And we also observed brinelling and other damage to the #1 bearing. This was the result of the crash.

After repairing the shaft damage from the crash and rebuilding the spindle, it ran like new.

Left photo: No stator housing.

Middle & right photo: New bearing and precision spacer provided.

It is of note that our customer sent their Mori Seiki spindle in without the stator housing. In this case it was a matter of convenience. They removed 5 bolts and shipped us the 50 lb sub-spindle cartridge. To ship the spindle with the stator housing, it would have involved a lot more labor and freight costs. We do prefer to have the stator housing for all spindle repairs for several reasons. But we realize this is not always possible. In this case we belt ran the spindle and balanced the spindle to full speed and we also supplied a new tail bearing with precision ground spacer ready for install.

In many cases we understand that the customer will utilize the OEM of their machine for the install of their rebuilt spindle. This is especially true with Mori Seiki spindles. So the spindle has to be perfect. And rightly so! This Mori ran beautiful having passed all of our most stringent test criteria. Along with a detailed three page Service Report, we included a Typical Bearing Run-In Procedure for reference. The spindle was coated with a light film of lubrication, wrapped tightly in anti-rust paper and packaged for safe transport back to the customer. After lying dormant in a box for nearly a decade, this spindle was once again ready for production!

For expert Mori Seiki NL repair, please email or call us at 1-1-603-483-0333 for a free, no obligation quote. We are fast, experienced, and our work is guaranteed.