Mori Seiki NMV Series Spindle Repair

At High Speed Technologies, Inc. we are distinguished in Mori Seiki NMV Series Spindle Repair and Rebuild. We are DMG Mori spindle experts, Call 1-603-483-0333. We have over 30 years of experience with Mori Seiki spindles and offer a full warranty with every repair. If your spindle is damaged, broken or providing poor part quality we can restore it to factory new condition. Need emergency repair? Ask about our QTA service.

At High Speed Technologies, Inc. we are distinguished in Mori Seiki NMV Series Spindle Repair and Rebuild. We are DMG Mori spindle experts, Call 1-603-483-0333. We have over 30 years of experience with Mori Seiki spindles and offer a full warranty with every repair. If your spindle is damaged, broken or providing poor part quality we can restore it to factory new condition. Need emergency repair? Ask about our QTA service. Mori Seiki NMV machines are excellent, very rigid, five axis machines specifically designed for five sided milling. Like most Mories these oil injection lubricated spindles run fast and they come with their own set of nuances. At HST we know them all. We will clean every minute orifice and hand lap the spacers the last micron or two for a perfect match. When you send us your spindle we will provide a thorough inspection and evaluation report at no charge. All critical surfaces will be measured to micron tolerances and only top name brand super precision spindle bearings will be used. You will get much more than just new bearings. Our comprehensive repair will have your old spindle performing like new. Worn or damaged taper? No problem. We can restore your damaged taper to exact OEM specifications. We are HSK experts and Big Plus certified. All grinding is done in-house on our Kellenberger grinding machine.

Mori Seiki NMV machines are excellent, very rigid, five axis machines specifically designed for five sided milling. Like most Mories these oil injection lubricated spindles run fast and they come with their own set of nuances. At HST we know them all. We will clean every minute orifice and hand lap the spacers the last micron or two for a perfect match. When you send us your spindle we will provide a thorough inspection and evaluation report at no charge. All critical surfaces will be measured to micron tolerances and only top name brand super precision spindle bearings will be used. You will get much more than just new bearings. Our comprehensive repair will have your old spindle performing like new. Worn or damaged taper? No problem. We can restore your damaged taper to exact OEM specifications. We are HSK experts and Big Plus certified. All grinding is done in-house on our Kellenberger grinding machine.

Some Featured Repairs

HST Job I-9127 Our customer crashed this DMG Mori NMV 500 in the “Z” axis with a 0.250 tool. Fortunately there was no damage to the shaft or housing. The customer could feel what they described as a “flat spot” when turning the spindle by hand. We discovered slight brinelling on the # 1 bearing. In this case the crash might have been a small blessing in disguise. When we opened the spindle up we discovered severe contamination in the # 1 & #2 bearings and failure was imminent. Catastrophic bearing failure while operating at high speed could have caused worse damage than the crash.

Heavy contamination is evident on the #2 bearing. Failure that might have caused worse damage could not have been far away.

All lubrication orifices are clogged with a sludge build up. These will be sparkling clean before it is assembled.

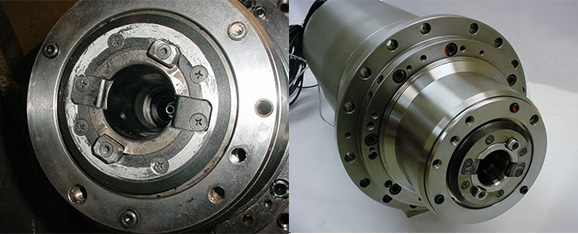

The spindle had a well-worn HSK 63 tool interface. The simultaneous contact interface was restored to new condition as can be seen in the before and after photos.

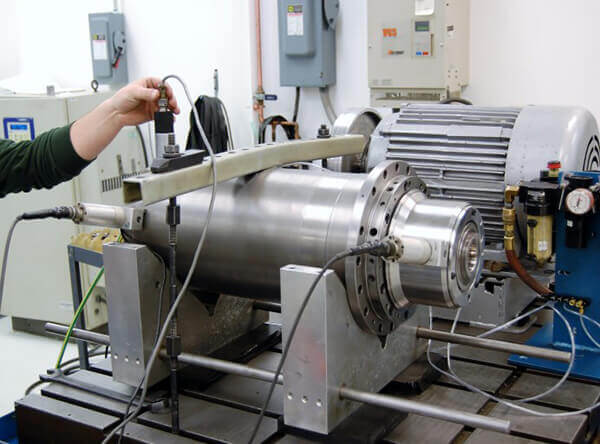

The spindle will receive only the best top name brand ABEC 7 Super Precision spindle bearings. In the case the front received a pair of NSK 70BRN10HTDUELP4Y bearings and the rear received a NTN 101HSKCONAP4 Precision Roller Bearing. After hand lapping the spacers for proper preload, setting capture and careful assembly the spindle was instrumented for run-in and testing.

How did it do? Excellent!! Acceleration was measured at 0.2272 g and velocity was at 0.0268 in/s.