Mori Seiki SH Series Spindle Repair

HST technicians provide expert Mori Seiki SH series spindle repair and rebuild including Mori SH-400, SH-403, SH-63 and others. We can repair your Mori Seiki SH series spindle back to OEM performance with an OEM equivalent warranty. 1-603-483-0333. Need emergency repair service for a crashed Mori Seiki spindle? We can help. Our repairs are fast, good and guaranteed.

If your Mori Seiki spindle has noisy bearings or if you feel increased vibration your spindle may be near a catastrophic failure. Other indications that your spindle may need repair or rebuilding include poor part finish. We replace all bearings with top name brand super precision spindle bearings. Worn springs, seals and critical surfaces are also replaced or restored to new condition. All Mori Seiki SH series spindles are high speed balanced to eliminate vibration.

After our repair, your spindle will perform like new. If you are experiencing bad finish and “chatter marks” our repairs will eliminate them. For 30 years HST has provided the CNC machining community with a high quality alternative to high price OEM spindle repairs. Spindle repair is what we do so we have to be good.

Who should you trust to repair your spindle? Before you chose an independent repair facility get the answers to these questions.

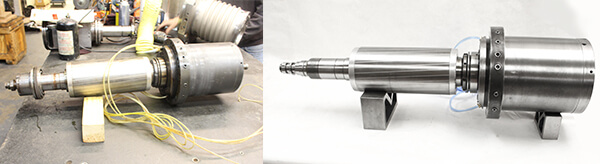

A completely repaired Mori Seiki SH-403 spindle ready to be crated and shipped to the customer.

See some featured repairs below.

Expert Mori Seiki Spindle Repair 800-248.4478 Full Warranty, Fastest Turn Around. OEM Trained technicians. Repairing Spindles since 1986.

Featured Repairs

Mori Seiki SH-403 Spindle Repair Job I-1247

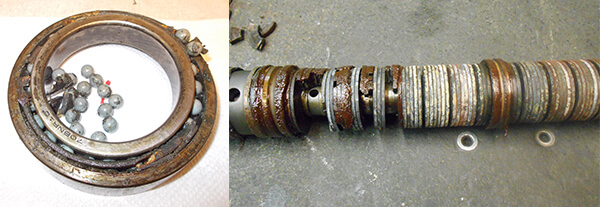

When we received this SH-403 spindle for repair we found 2 major issues. The shaft could still turn but the bearings were very close to catastrophic failure. A catastrophic bearing failure can result in spinning the inner race on the shaft journal and the added cost of GPG to the repair.

The tool clamp system was in very bad condition. The gripper fingers were badly worn and there was no pull force. When we took the drawbar out of the spindle we found that most of the Belleville springs had failed from fatigue.

The #1 bearing was very close to complete failure. Chunks of Belleville springs are missing from this Mori Seiki SH-403 spindle.

The face of the spindle was also a little dinged up so we gave it a kiss grind. When we were done the spindle ran great.

Front vibration readings were 0.0200 in/sec and the run out on our 300 mm test bar was just 1µm.

One of the reasons why we love Mori Seiki spindles is because they come out so great just about every time!

Mori Seiki SH-403 Spindle Repair Job I-0057

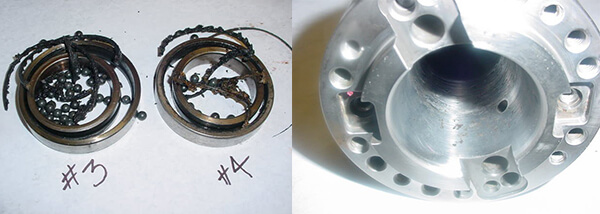

The number 3 and 4 bearings suffered catastrophic failure. That is the cages no longer kept the rolling elements properly spaced. Additionally the CAT 40 taper suffered damage from debris clinging to the tool surfaces during an ATC. The taper damage was severe enough to require full restoration using our GPG process.

Catastrophic bearing failure and taper damage are just a few of things damaged spindles need repaired.

Fretting was also observed on the front bearings and may have been part of the original problem. Fretting is an indication of improper fit. And sure enough when measured we found the shaft journal to be undersized. Our GPG process can correct undersized or damaged journals.

Because these bearing were in the back of the spindle the part finish may have been adequate while they were failing. However, we imagine that these bearings were noisy and generated vibration. CNC operators should be alert to changes in the machine sound to prevent additional damage.

Fretting is observed on the inner race of this spindle bearing. Fretting is caused by vibrations between two close fitting parts. On a bearing ID it is the result of a fit that is too loose. There should be no vibration between the race ID and the shaft journal.

Mori Seiki SH-403 Spindle Repair Job I-19378

This spindle had a Big Plus CAT 40 taper and the taper was cracked. A new shaft was very expensive and many weeks away. At HST we have experience doing deep micro welds on cracked tapers. So we were able to repair this SH-403 shaft in a just few days. That was back in January of 2012. As of this writing over 3 years later the spindle is still working.