Toyo Spindle Repair and Rebuild

Your Toyo spindle is in expert hands with the factory-trained, Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of Toyo spindles to original factory performance. Need it fast? We can repair your spindle within three days of customer approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Your Toyo spindle is in expert hands with the factory-trained, Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of Toyo spindles to original factory performance. Need it fast? We can repair your spindle within three days of customer approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are some common Toyo spindle performance issues that we resolve:

- Noisy or contaminated bearings

- Increased vibration

- Coolant obstruction

- Pilot ID damage

- Burned stator

- Internal coolant leak

- Poor part finish

- Failed seal

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will include replacing or restoring all worn drawbar springs, seals and critical surfaces. Then we perform high-speed balancing to eliminate vibration, extend life and improve part quality. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986.

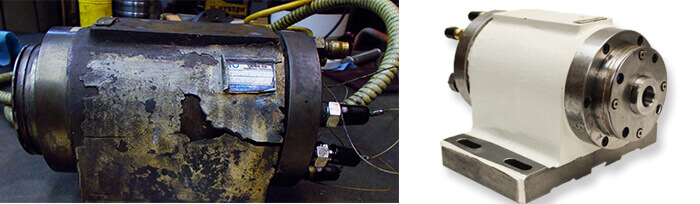

This Toyo HFD05-37 spindle was sent to us from a return customer in Asia. We’ve repaired dozens of Toyo spindles for them over the years. This particular one was sent to us with a note: “Spindle is running sluggish!” Although the shaft turned freely, it rotated with significant stiffness. The main reason for this was the simple fact that it was very worn. Internally and externally this Toyo spindle was in need of attention.

We thoroughly test all Toyo stators upon evaluation. Although this stator passed all testing, we still removed it from the main housing so we could replace the stators coolant jacket seals and clear any obstruction within the coolant pathways.

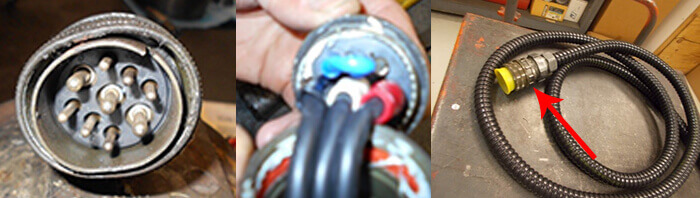

Many times the power connector assembly is damaged upon our receipt. This connector was crushed. Locating and procuring a new connector with the proper pin out and identical connector housing can involve tedious hours of flipping through the pages of catalogues. But when we say that we return your Toyo spindle to new condition, we mean it.

Most of the Toyo wheelhead spindles we rebuild have lived a rough life. More often than not the data labels are corroded and illegible, such as this one. If our customer accidentally attached the coolant line to the lubrication inlet it could quickly destroy the bearings. We provide new data tags to prevent this from happening.

We replaced all bearings and seals with new and also changed out the original power cord harness with four feet of new Liquid-Tight conduit. We performance tested the spindle at max speed (50,000 RPM) and gave it a fresh coat of industrial epoxy paint. This Toyo HFD05-37 spindle looked and ran like new!

For expert Toyo repair, email [email protected] or call us at 1-603-483-0333 for a quote. We are fast, experienced, and our work is guaranteed.