Mazak Variaxis Series Spindle Repair & Rebuild

We provide expert Mazak Variaxis Series Spindle Repair and Rebuild to OEM like new condition. Call 800.248.4478. Our Variaxis repairs come with a one year warranty. If your spindle has bad or worn bearings we will replace them with top name brand super precision ABEC 7 spindle bearings. Our in-house grinding can repair worn tapers and journals. We can even repair some shafts damaged from a crash. We have specialized in repairing spindles for over 30 years. If you need an emergency repair due to a critical machine down ask for our QTA service. Please see a few examples of our Variaxis repairs below.

We provide expert Mazak Variaxis Series Spindle Repair and Rebuild to OEM like new condition. Call 800.248.4478. Our Variaxis repairs come with a one year warranty. If your spindle has bad or worn bearings we will replace them with top name brand super precision ABEC 7 spindle bearings. Our in-house grinding can repair worn tapers and journals. We can even repair some shafts damaged from a crash. We have specialized in repairing spindles for over 30 years. If you need an emergency repair due to a critical machine down ask for our QTA service. Please see a few examples of our Variaxis repairs below.

If you send us a spindle we will perform a comprehensive evaluation and send a full report to you at no charge or obligation. The report will provide a detailed analysis of what we found and what work we recommend.

Our technicians have years of experience repairing Mazak Variaxis spindles. They are certified in relevant skill sets such as balancing and vibration analysis. If you have a spindle that needs repair call HST at 1-603-483-0333 for fast turnaround and OEM quality without the cost of an OEM repair.

The Variaxis is an excellent and versatile 5 axis vertical machining center. It is designed along Mazak’s “Done in One” philosophy. Fully synchronized five axis machining permits the machine to turn out complex contoured parts with one set-up.

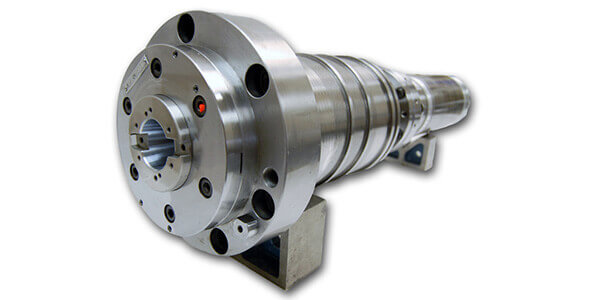

Variaxis Spindle Restored to OEM New condition

Some Featured Repairs

HST Job I-0362

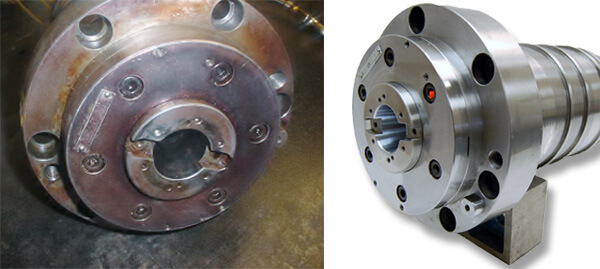

This damaged Variaxis spindle came from one of our customers in Asia. When we received it the spindle turned freely. But when we checked the run out on the taper with our certified 300MM test bar, the problem was obvious. This spindle had more than 10µm on the taper face. There is no way this Variaxis spindle could make high precision parts. The taper definitely needed GPG restoration.

The rear roller bearing had failed and the inner race had spun on the shaft. This wore down the shaft OD by 0.035mm. The loose fit now allowed the rotor to wobble around and make contact with the stator. Fortunately the stator was not damaged and the rotor was repairable.

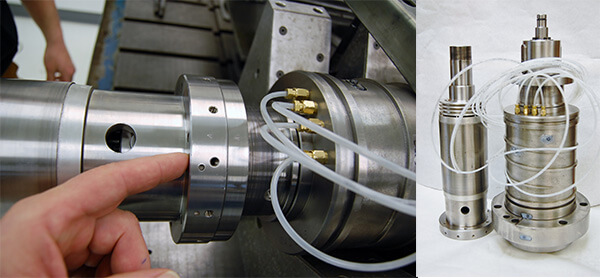

The Variaxis is an oil mist lubricated spindle. At HST we will remove each jet and meticulously clean every orifice and all of the internal passages. New lines and fittings are provided with each repair.

At HST we will remove each jet and meticulously clean every orifice and all of the internal passages.

Of course we will repair this spindle by replacing all of the bearings with top name brand ABEC 7 Super Precision Spindle Bearings, set the preload and capture to micron tolerances.

The rotor on the Variaxis is bolted to the main spindle and it cantilevers out pretty far. So we detach the rotor for running and balancing the spindle at full speed. After run-in is complete the rotor is attached and run-out is adjusted.

Checking the run-out on the back of a Variaxis stator

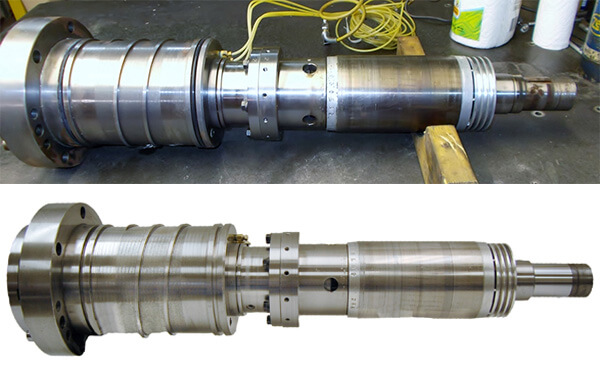

Mazak Variaxis before and after repair

When Job I-0362 was completed the spindle run out at the end of the test bar was only an amazing 3µm. Amazing work! The vibration acceleration was 0.03870 in/sec.

HST Job I-9963

This Mazak Variaxis spindle was the first one we received from our customer in Asia, and on arrival the spindle showed definite signs of wear and tear. There were indications of a minor crash including a damaged gripper assembly and the bearings on this spindle were just starting to show signs of failure.

At first look the gripper assembly appears OK. But Die Penetrant examination reveals a hair line crack

In this photo you can see why the Variaxis is so stiff. The bearing stack is long, utilizing the maximum possible separation between tandem pairs. Each tandem pair has its own spacer and then they are mounted back to back with very long spacers in between.

After the spindle was repaired and assembled we placed it on our test bench . The numbers taken throughout the testing process indicated the spindle was performing like new. Unfortunately the customer wanted this spindle shipped in two pieces. So the rotor had to be removed from the main spindle body for shipment. We provided careful instructions so the customer could re-align everything in the correct way.

Noting marriage marks before disassembling. Variaxis spindle ready for shipping.

At HST we repair all make and models of Mazak spindles. We will only use top name brand ABEC 7 super precision spindle bearing in your repair. So if you have a problem give us a call 1-603-483-0333 anytime during business hours we’ll answer the phone.