At HST we know we have a number of very good competitors and we respect them. But a little while back we had a firsthand experience with SETCO that gave us some insight as to their corporate personality and perhaps part of the reason why so many customers choose HST to repair their SETCO spindles.

At HST we know we have a number of very good competitors and we respect them. But a little while back we had a firsthand experience with SETCO that gave us some insight as to their corporate personality and perhaps part of the reason why so many customers choose HST to repair their SETCO spindles.

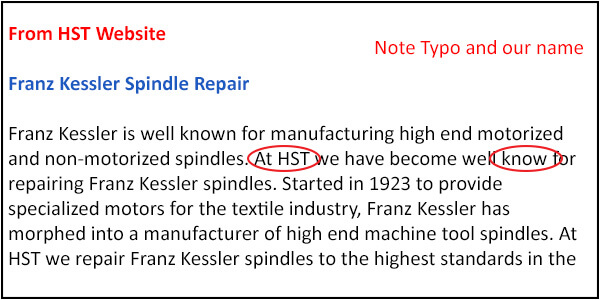

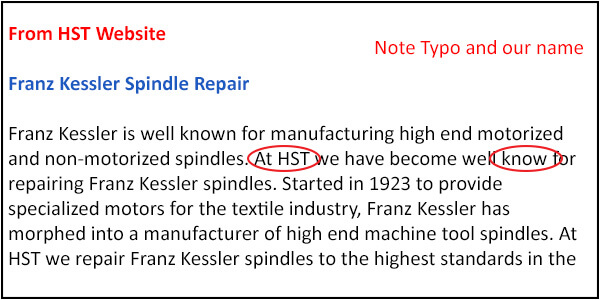

Check out what SETCO did. Below is an excerpt from our Franz Kessler Repair page.

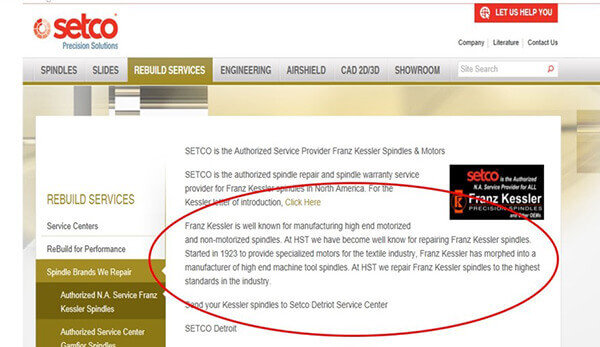

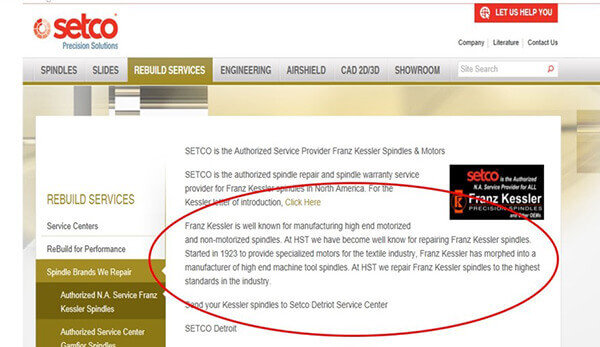

Can you imagine our surprise when we saw that SETCO said those exact same words on their web page? Below is a screenshot from SETCO’s Franz Kessler web page. While we appreciate SETCO saying nice things about us, we wonder about the character, integrity and smarts of a company that would plagiarize our website word for word including our name and typos.

Well, we weren’t going to tell them that their website said that HST repairs spindles to the highest standards in the industry. But unfortunately after about a year they must have looked at their website and decided to write their own copy. We wish you could have seen it. So here is an actual screen shot of their website.

SETCO Web page extolling the quality of HST spindle repairs. Thanks SETCO for saying such nice things about us. Sorry we can’t say the same for you.

While some shops have different levels of repair and you may pay extra for their “Gold Line” repair HST only has Gold Line repair. All bearings are always replaced with top name brand ABEC 7 super precision spindle bearings. Our “basic repair” is comprehensive and includes replacing or restoring all worn springs, seals, testing pull force and restoring critical surfaces. After that the spindles are run-in and to eliminate vibration, extend life and improve part quality, all SETCO spindles are high speed balanced. All sensors, encoders and transducers are tested and adjusted if needed.

After our repair, your spindle will perform like new, guaranteed! If you are experiencing bad finish and “chatter marks” our repairs will eliminate them. For over 30 years HST has provided the CNC machining community with a high quality alternative to high priced OEMs.

At HST we know we have a number of very good competitors and we respect them. But a little while back we had a firsthand experience with SETCO that gave us some insight as to their corporate personality and perhaps part of the reason why so many customers choose HST to repair their SETCO spindles.

At HST we know we have a number of very good competitors and we respect them. But a little while back we had a firsthand experience with SETCO that gave us some insight as to their corporate personality and perhaps part of the reason why so many customers choose HST to repair their SETCO spindles.

Check out what SETCO did. Below is an excerpt from our Franz Kessler Repair page.

Can you imagine our surprise when we saw that SETCO said those exact same words on their web page? Below is a screenshot from SETCO’s Franz Kessler web page. While we appreciate SETCO saying nice things about us, we wonder about the character, integrity and smarts of a company that would plagiarize our website word for word including our name and typos.

Well, we weren’t going to tell them that their website said that HST repairs spindles to the highest standards in the industry. But unfortunately after about a year they must have looked at their website and decided to write their own copy. We wish you could have seen it. So here is an actual screen shot of their website.

SETCO Web page extolling the quality of HST spindle repairs. Thanks SETCO for saying such nice things about us. Sorry we can’t say the same for you.

While some shops have different levels of repair and you may pay extra for their “Gold Line” repair HST only has Gold Line repair. All bearings are always replaced with top name brand ABEC 7 super precision spindle bearings. Our “basic repair” is comprehensive and includes replacing or restoring all worn springs, seals, testing pull force and restoring critical surfaces. After that the spindles are run-in and to eliminate vibration, extend life and improve part quality, all SETCO spindles are high speed balanced. All sensors, encoders and transducers are tested and adjusted if needed.

After our repair, your spindle will perform like new, guaranteed! If you are experiencing bad finish and “chatter marks” our repairs will eliminate them. For over 30 years HST has provided the CNC machining community with a high quality alternative to high priced OEMs.