Chevalier Spindle Repair and Rebuild

Your Chevalier spindle is in expert hands with the factory-trained technicians at High Speed Technologies, Inc. We have repaired many Chevalier spindles to new condition! Need it fast? We offer a Quick Turn Around service! All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Your Chevalier spindle is in expert hands with the factory-trained technicians at High Speed Technologies, Inc. We have repaired many Chevalier spindles to new condition! Need it fast? We offer a Quick Turn Around service! All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are just some of the common Chevalier spindle performance issues that we resolve:

- Noisy bearings

- Contaminated bearings

- Increased vibration

- Damaged shaft

- Overheating

- Poor part finish

- Worn pulley

- Shaft end play

- Shaft seized

- Excessive runout at Taper ID

- Preventative Maintenance

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will minimally include replacing all seals, grinding bearing spacers for proper preload and restoration of damaged shaft surfaces. Then we perform high-speed balancing to eliminate vibration, extend spindle life and improve finish quality on parts. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986.

Chevalier Spindle before and after

When our customer, a manufacturer of High Reliability Variable Capacitors out of Arizona called us, they were concerned about their Chevalier VMC spindle. They explained that they had left the spindle running at 10,000 RPM and then when they turned their back it had tripped a “speed” alarm on the machine. After re-setting the machine the spindle now sounded strange to them. So in turn, they shipped the spindle in for evaluation.

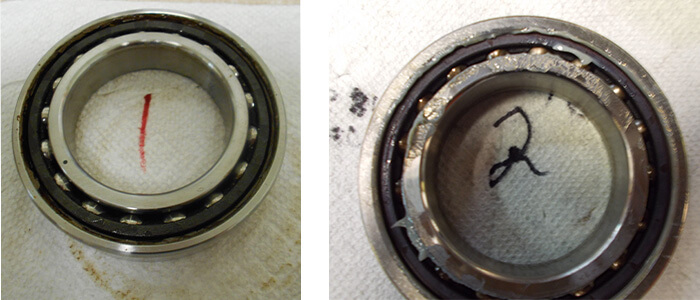

Crashed bearings on a Chevalier spindle

When the Chevalier VMC spindle hit our dock, we performed an initial inspection and determined that the bearings were in fact damaged. So we proceeded with dismantling the spindle and did a full evaluation. Upon close examination of each bearing we could see that they had become contaminated with cutting fluid and particulate over time. Eventually the bearings had reached the point of degradation where it triggered the machine alarm and our customer could even hear an audible difference.

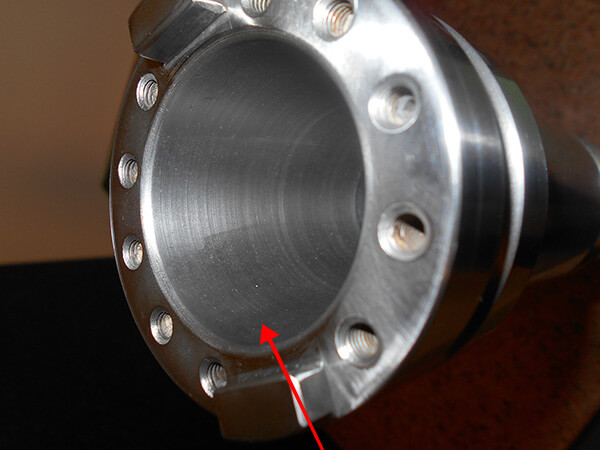

The shaft taper ID required a kiss grind.

We also noted that the shaft taper ID was scored at some point during a tool change. We were able to eliminate the damage with a Kiss grind on our Kellenberger Universal Grinder. After replacing all bearings and seals the spindle ran like new. We also restored the drawbar pull force by replacing the springs and precision gripper balls. When the spindle was returned to the customer, we could say with confidence that it was as good as new, if not better! This Chevalier Vertical Milling spindle is still cutting chips and producing quality parts and it’s been four years since the repair!

Here at High Speed Technologies we love a happy customer! For expert Chevalier spindle repair, please email or call us at 603-483-0333 for a free, no obligation quote. We offer one-year warranty and Quick-Turn-Around. We are fast, experienced and our work is guaranteed!!