CMS GR-3397 Spindle Repair and Rebuild

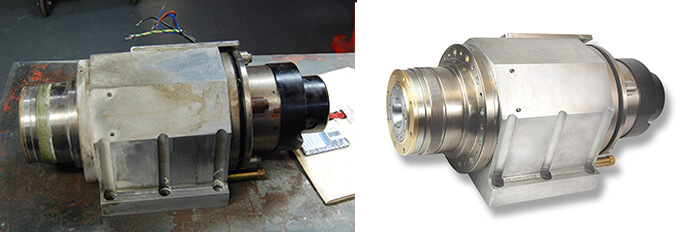

CMS GR-3397 before and after

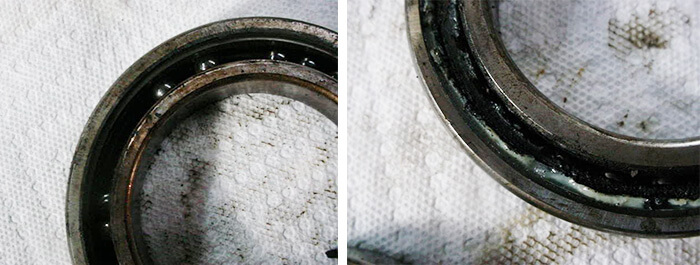

Upon receipt the shaft in this CMS GR-3397 spindle was seized solid! When the spindle was disassembled we learned that the #1 bearing had failed catastrophically. The ball cage was broken in several places, locking things up. All other bearings were also severely contaminated and damaged. Most of the grease lubrication was washed out of each bearing by cutting fluid which is used in the customers manufacturing process. All bearings and O-rings were replaced with new.

CMS GR-3397 bearing failure: The grease lube was washed and contaminated!

Along with the bearing failure, we also found the shaft taper and shaft bore to be rusted and visibly worn. After a thorough cleaning and closer inspection however, we determined that it was OK for re-use. The Belleville washers and gripper assembly (collet) on the drawbar were intact but severely corroded and worn. We replaced these items with brand new. All seals were also replaced.

Gripper assembly (collet) was replaced with new.

For expert CMS GR-3397 spindle repair, please email or call us at 603-483-0333 for a free, no obligation quote. We offer Factory Equivalent Warranty and Quick-Turn-Around. We are fast, experienced and our work is guaranteed!!