Colombo Spindle Repair & Rebuild

Your Colombo spindle is in expert hands with the factory-trained technicians at High Speed Technologies, Inc. We have repaired dozens of Colombo spindles to original factory performance. Need it fast? We can repair your spindle within three days of estimated approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Your Colombo spindle is in expert hands with the factory-trained technicians at High Speed Technologies, Inc. We have repaired dozens of Colombo spindles to original factory performance. Need it fast? We can repair your spindle within three days of estimated approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are some common Colombo spindle performance issues that we resolve:

- Noisy or contaminated bearings

- Failed bearing

- Over heating

- Taper ID damage or wear

- Low draw force

- Poor part finish

- Failed seal

- Failed proximity sensor(s)

- Broken fan

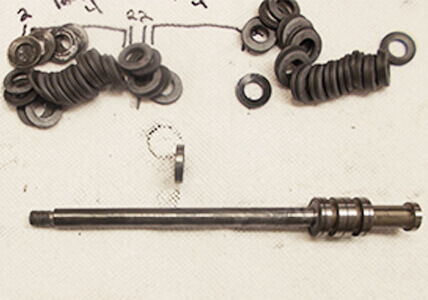

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will include replacing or restoring all worn drawbar springs, seals and critical surfaces. Then we perform high-speed balancing to eliminate vibration, extend life and improve part quality. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986.

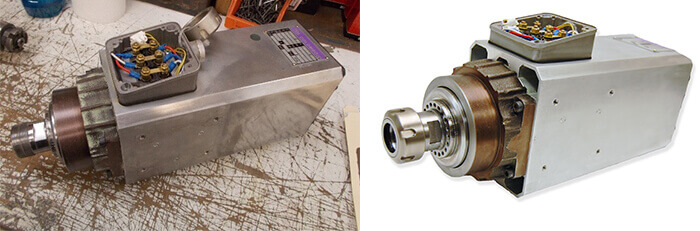

Colombo RS110.22 ISO30

Colombo spindle before and after

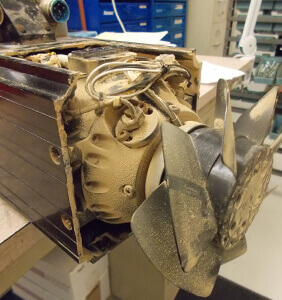

Upon arrival you could clearly tell this Colombo spindle was used to rout wood! The housing was covered in a nice coat of wood chips and dust. Further inspection revealed damage to the shafts taper ID and front bearing shoulder. Both of these surfaces were kiss grind on our very own kellenberger grinder. The Belleville washers on the drawbar were fatigued and the gripper (collet) was also well worn, w replaced both items with new.

All Belleville washers will be replaced with new

Housing covered in wood debris

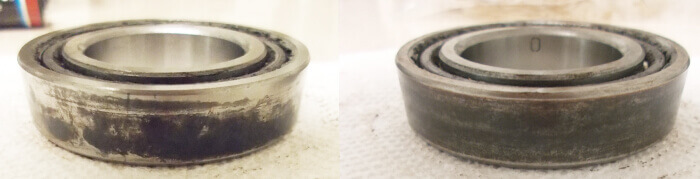

The main problem with this spindle was the bearings. The lubrication within each bearing was very dry and contaminated with wood particulate. This was no surprise. Routing spindles like this are usually well used by the time they are sent in for repair. The fretting observed on the outer race of the rear bearing pair was due to a combination of vibration and a looser fit within the housing bore. We replaced all bearings with new.

Fretting on outer races of bearings # 3 & 4

We know a down spindle means down production for our customers. That is why High Speed Technologies strives for the fastest turnaround time in the industry. This customer was very pleased: “Turned it on, worked quickly & smoothly! Great! One doesn’t often find this level of service anywhere anymore! You guys can be proud! I have been left with a very warm feeling from your people & your company.”

Colombo RV110.2

Colombo RV110.2 before and after

This spindle came off a Multicam MG 3 axis machine. The most common cause of failure for a routing spindle is worn and contaminated bearings. That was the case for this Colombo spindle. Over time the bearings became contaminated and worn. Prior to disassembly the bearings sounded very poor when the shaft was rotated by hand. Foreign particulate was observed throughout the grease in all bearings as you can see in the pictures below. All bearings and seals were replaced with new.

Contaminated bearings in a Colombo spindle

Along with the contaminated bearings, we also measured runout at the shaft taper in excess of 40 micron! We Kiss ground this surface and squared the shoulder in house on our Kellenberger grinder. This customer too had wonderful things to say: “Thank you very much for all the work and effort you made to repair the spindle. I installed it and I am very pleased, the repair was excellent.”

Severe runout measured at shaft taper and shoulder.

As you can imagine, here at High Speed Technologies we love a happy customer! For expert Colombo spindle repair of any make or model, please email or call us at 603-483-0333 for a free, no obligation quote. We offer one-year warranty and Quick-Turn-Around. We are fast, experienced and our work is guaranteed!!