Mitsui Seiki Spindle Repair and Rebuild

Your Mitsui Seiki spindle is in expert hands with the factory-trained, Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of Mitsui Seiki spindles to original factory performance. Need it fast? We can repair your spindle within three days of estimated approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Your Mitsui Seiki spindle is in expert hands with the factory-trained, Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of Mitsui Seiki spindles to original factory performance. Need it fast? We can repair your spindle within three days of estimated approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are some common Mitsui Seiki spindle performance issues that we resolve:

- Noisy or contaminated bearings

- Failed bearing

- Over heating

- Taper ID damage

- Low draw force

- Poor part finish

- Failed seal

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will include replacing or restoring all worn drawbar springs, seals and critical surfaces. Then we perform high-speed balancing to eliminate vibration, extend life and improve part quality. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986.

Spindle arrived completely disassembled

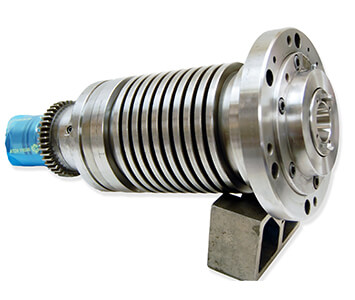

Mitsui Seiki after repair

This Mitsui Seiki was sent to us by a quality tool and die maker out of Pennsylvania. When we opened the box we were surprised to see that someone else had already taken it apart for us. It was completely dismantled. The first thing we had to do was sort through the box to ensure that none of the critical components were missing. After this we turned our attention to the reason the spindle failed. The #1 bearing was destroyed! Evidence suggested that cutting fluid and particulate had migrated into the front bearing over time and eventually resulted in its failure. The shafts taper was also dented and well worn! We were able to repair this shaft surface with a Kiss grind. Of course we also replaced all of the bearings and seals with new. We offered to rebuild the drawbar assembly but the customer respectfully declined because they were confident the Belleville’s and Gripper still had some life in them.

Lube washed out and degraded.

The shaft taper ID will need a kiss grind.

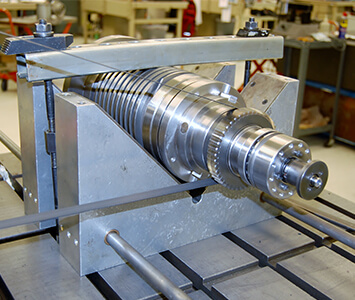

Once this Mitsui Seiki spindle was assembled we ran it up on our test bench for 8 hours. After trim balance, the spindle passed all tests with flying colors! It was now ready to ship back to the customer. It was securely packaged for safe transport. Once the customer received their spindle they were very pleased with High Speed Technologies work and had this to say, “Their workmanship is outstanding, far better than any rebuilder I have used over the past 30 years…. they have answers when you need them.”

Mitsui Seiki spindle ready for shipping

Spindle being tested

Here at High Speed Technologies we love a happy customer! For expert Mitsui Seiki spindle repair, please email or call us at 603-483-0333 for a free, no obligation quote. We offer one-year warranty and Quick-Turn-Around. We are fast, experienced and our work is guaranteed!!